Introduction

The abbreviation of SII Israel Standards Institute, full name: The standards institute of Israel, all electronic and electrical products exported to Israel must obtain SII certification. As Israel is also a member of IEECEE-CB, they recognize and accept CB test reports issued by their IECEE-CB member countries.

The necessity of SII certification

The term 'mandatory' in Israel's mandatory certification needs to be understood from multiple perspectives. According to the regulations issued by the Israeli government, all goods entering Israel must undergo corresponding cargo inspections by SII institutions to confirm that they meet Israel's national standards. The Israeli Industrial and Trade Labor Agency calls this certification process "presumption of conformity", where goods are inspected in batches, meaning that each imported goods must be inspected. The test certificate issued during the last inspection can be used for the next inspection, but cannot directly replace the current inspection. It will only shorten the time the goods stay at customs, in order to save customers some customs clearance fees (usually around 40 days for SII goods inspection).

Applicable product scope

household appliances

Switches and automatic conversion devices for cables, wires, and instruments

Complete equipment and joint device

Lighting technology products

Adjust protective equipment

Low voltage control device

Low-power transformer

Welding equipment

Personal computers and laptops

Chemical supply source

Small and medium-sized engines

measuring tool

Electronic instruments and equipment

game console

Information technology equipment and office equipment

Cinematography equipment and tools

Radio communication, radio broadcasting, television equipment

Communication and fax equipment

Low voltage complete equipment, high voltage equipment

Electrothermal equipment

Application Process

1. Apply

2. Sample testing

3. Submit test report

4. Factory coaching before factory inspection

5. On site inspection

6. Certificate issuance

Application materials

Manufacturers of electrical products must submit a formal application that includes at least the following information in order to obtain approval for the marking of an electrical appliance produced in their factory:

A、 Overview of the organizational structure of the manufacturing plant (material branch diagram of the organizational structure);

B、 Explanation of the specifications and standards on which the product is manufactured;

C、 Description of production equipment;

D、 Instructions for testing equipment;

E、 If necessary, measurement calibration procedures and equipment specifications;

F、 Explanation of quality control measures and their quality control standards adopted to supervise consistent manufacturing;

G、 If not all products are manufactured in the applicant's factory, the manufacturing stages carried out in the manufacturer's factory and by other manufacturing factories should be separately explained;

H、 A list of test items that can be conducted in the applicant's laboratory and a list of equipment available for these tests.

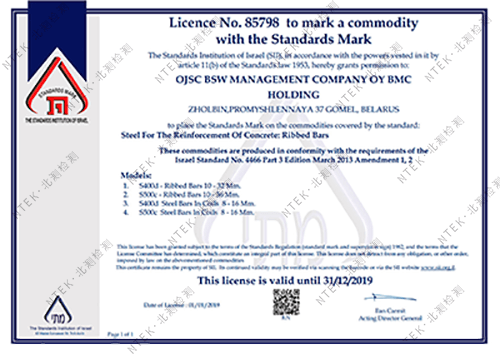

Certificate Information

Copyright © Dongguan Di'en Testing Co., Ltd. Technical Support: Dongguan Guangsu Network Guangdong ICP No. 15086094-1

Mailing Address: Di'en Testing, Wusha Community, Chang'an Town, Dongguan City

Metrology & Calibration Contact:

Mr. Tai - Mobile: 13760389645

Ms. Li - Mobile: 15817661429

Product Testing Contact:

Ms. Yang - Mobile: 18123900885

Reliability, Failure Analysis, & Materials Testing Contact

Mr. Ye - Mobile: 13613003484

Copyright © Dongguan Di'en Testing Co., Ltd. Technical Support: Dongguan Guangsu Network Guangdong ICP No. 15086094-1