High Accelerated Life Testing (HALT) is a process that uses a rapidly changing oscillation system between high and low temperatures to reveal design defects and deficiencies in electronic and mechanical components. The purpose of HALT is to identify the functionality and destructive limits of a product in the early stages of development, in order to optimize its reliability. HALT is not a qualified or unqualified test, but a tool to assist design engineers in improving product reliability. There is no pre-set limit, and the limit is determined by the product, gradually increasing stress until failure. During the test, the product needs to be monitored. HASS (Highly Accelerated Stress Screening) is a high acceleration stress screening performed on products after obtaining the operating or failure limit value through HALT testing, where the stress is lower than that of HALT testing.

Product scope

Halt/Hass testing can be conducted for modules, communication terminals, components, and complete machines of electrical and electronic, instrumentation, automotive, and aerospace products.

Relevant qualifications

CNAS,CMA

Test Standard

GB/T 29309;

DKBA1141 "HALT Test Specification for Communication Products"

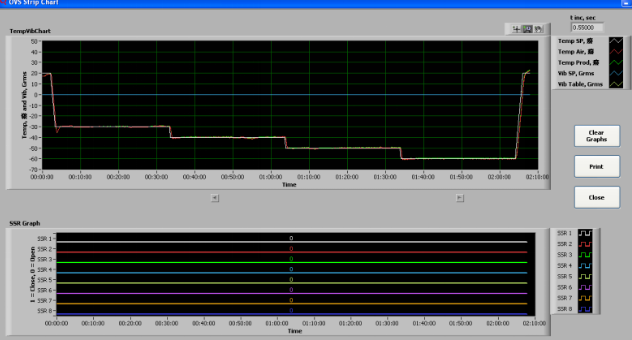

Photo

Copyright © Dongguan Di'en Testing Co., Ltd. Technical Support: Dongguan Guangsu Network Guangdong ICP No. 15086094-1

Mailing Address: Di'en Testing, Wusha Community, Chang'an Town, Dongguan City

Metrology & Calibration Contact:

Mr. Tai - Mobile: 13760389645

Ms. Li - Mobile: 15817661429

Product Testing Contact:

Ms. Yang - Mobile: 18123900885

Reliability, Failure Analysis, & Materials Testing Contact

Mr. Ye - Mobile: 13613003484

Copyright © Dongguan Di'en Testing Co., Ltd. Technical Support: Dongguan Guangsu Network Guangdong ICP No. 15086094-1